Supply Chain Page

With an aim to resolve the problem of the increasing costs of supply chain in manufacture firm, an integrated supply chain management model, driven by market demand, is developed in this paper, based on the analysis of existing integrated models of supply chain. The management model integrates purchase, production and sale plans with logistics plans by logistics chain. In order to build this integrated supply chain planning model, an integrated supply chain system which contains the inside management system and the outside supply chain system of manufacturing firm is proposed to describe the supply chain process, and a conceptual framework of integrated supply chain planning is also designed. This paper uses a three-stage integrated supply chain planning model to make supply chain plans, and a classification evaluation model is also suggested to analyze the feasibility of planning by comparing the planned cost with the anticipated cost. Research results indicate that this three-stage integrated supply chain planning model can manage and control the costs of supply chain for manufacturing firms very well.?

We address a scheduling and routing problem faced by a third-party logistics provider in planning its day-of-week delivery schedule and routes for a set of existing and/or prospective customers who need to make shipments to their customers (whom we call “end-customers”). The goal is to minimize the total cost of transportation and inventory while satisfying a customer service requirement that stipulates a minimum number of visits to each customer each week and satisfaction of time-varying demand at the end-customers. Explicit constraints on the minimum number of visits to each customer each week give rise to interdependencies that result in a dimension of problem difficulty not commonly found in models in the literature. Our model includes two other realistic factors that the third-party logistics provider needs to consider: the cost of holding inventory borne by end-customers if deliveries are not made “just-in-time” and the possibility of multiple vehicle visits to an end-customer in the same period (day).

We develop a solution procedure based on Lagrangian relaxation in which the particular form of the relaxation provides strong bounds. One of the subproblems that arises from the relaxation serves to integrate the impact of the timing of deliveries to the various end-customers with inventory decisions, which not only contributes to the strong lower bound that the relaxation provides, but also yields a mathematical structure with some unusual characteristics; we develop an optimal polynomial-time solution procedure for this subproblem. We also consider two variants of the original problem with more restrictive assumptions that are usually imposed implicitly in many vehicle routing problems. Computational results indicate that the Lagrangian procedure performs well for both the original problem and the variants. In many realistic cases, the imposition of the additional restrictive assumptions does not significantly affect the quality of the solutions but substantially reduces computational effort.

A contingency is a randomly occurring crises event such as a national disaster, civil disorder, best replica watches or military invasion that creates a major threat to the safety and security of a population that requires immediate responsive operations that include the development and maintenance of supply chains to provide the logistics support functions. A method for quantifying the reliability of supply chains for contingency logistics systems is developed based on reliability interference theory. Supply chain reliability is defined as the probability of the chain meeting mission requirements to provide the required supplies to the critical transfer points within the system. The authors consider a flow of supplies that are deployed to a distribution center from which allocations are then made to n sites, each being engaged at a high operational tempo to meet the mission requirements of the..

Logistics chains are constantly changing to facilitate increasingly global movements. In qualitative terms, long term trends in logistics services indicate a growing degree of product customization and an increased responsiveness in order delivery. These trends impact on the development of technology and the growth of welfare in different world regions in different ways. This paper drafts a research agenda which will help to improve understanding of the interrelationships between trade, logistics, transport, and regional development at a global scale. Rather than being an exhaustive or detailed inventory of trends, the paper provides a focus on "supply chain by thinking." The key starting point is the need for more and more efficient transportation and sophisticated logistics processes. Three subjects are treated: First, the strategic implications of borderless supply chain management on the choice of alternative logistics structures in supply chains are considered; second, the possible impacts of the expected changes in supply chain processes upon regional economic activities are examined; third, the impacts of changes in global logistic processes on the transportation system and, in turn, on the environment are explored. This discussion leads to the identification of some new research challenges in the field of transportation and logistics.?

SUPPLY CHAIN MANAGEMENT

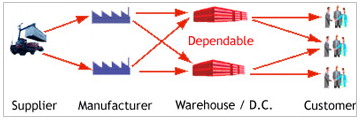

What is Supply chain management? A supply chain is the group of components (suppliers, distribution points, transportation providers) necessary to bring your product from its raw material state to the end user.

Supply chain management is the term used for controlling and regulating your supply chain.

A simple supply chain model consists of four components:

Weinberg replaces supply chain consultants for the Warehouse / Distribution center piece of your supply chain puzzle. We will talk to you about your needs, assess your current warehousing and distribution needs, and make recommendations on how you can make simple adjustments to save you time and money while increasing your service levels and efficiency. We even offer transition assistance to help you notify suppliers, vendors, and clients.

THE SUPPLY CHAIN MANAGEMENT AND LOGISTICS CHALLENGE

Nearly every organization faces supply chain management challenges. Managing costs, sourcing cost effective transportation, and deciding whether or not you need your own warehouse or storage space are all major issues.

What if all you had to worry about were production and sales?

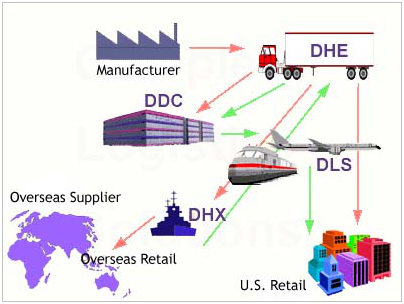

As your warehousing and logistics provider, DDC can help you manage:

For general inquiries, please contact us at (+65) 64234662 or

email us at Singapore@weinberg.com.sg